Custom silicone molds

Silicone specification

In our production we only use high quality platinum-based professional food/medical grade EU silicones so our customers are assured they receive molds with excellent end-product qualities and performance. The curing agents available are peroxide-curing and addition-curing types. Moulded parts can be produced in hardnesses from 30 Shore to 80 Shore. The properties of the material and the areas of application meet our silicone compounds:

- Large operating temperature range (can withstand temperatures from -50 to +250 degrees)

- Resistant to weathering, ageing and UV

- Very good physiological compatibility

- Controlled hardeness (from 15 SHORE to 40 SHORE)

- Food/Medical grade

Production process

We provide all-in-one service, from the developement of idea in cooperation with our customers to making first prototype. Here are default steps of our production process:

- Generation of the idea, its revision

- CAD modelling, 3D modelling, technical drawings for a moulded part

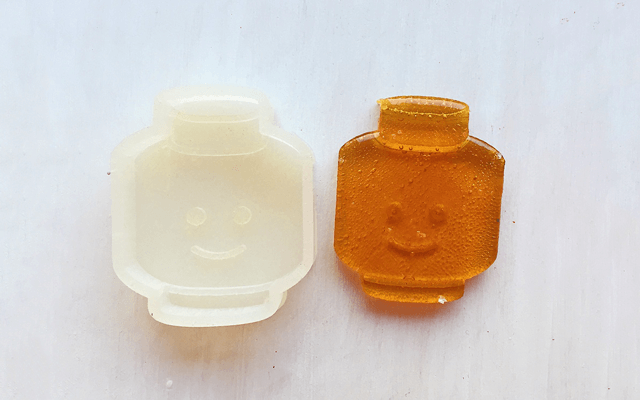

- Creation of small series

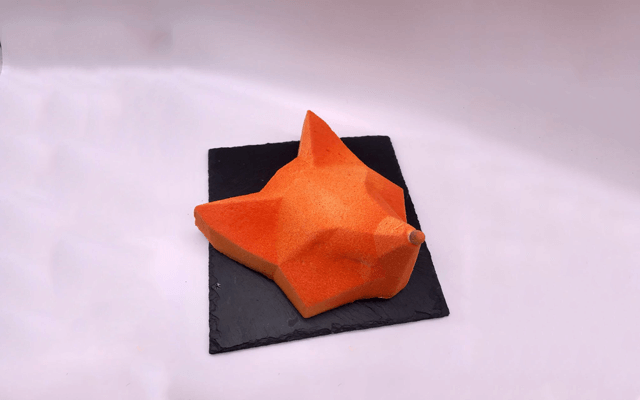

- Creation of prototype

- Master model creating, postprocessing

- Silicone mold making

Relative articles: