Custom solutions for confectioners

Our team carries out complex projects for professional confectioners of various degrees of complexity. With our own equipment for laser cutting, engraving and 3d printing, as well as experience in the production of silicone molds, we can guarantee that the production deadlines are met. In most cases, we manage to complete production earlier than agreed.

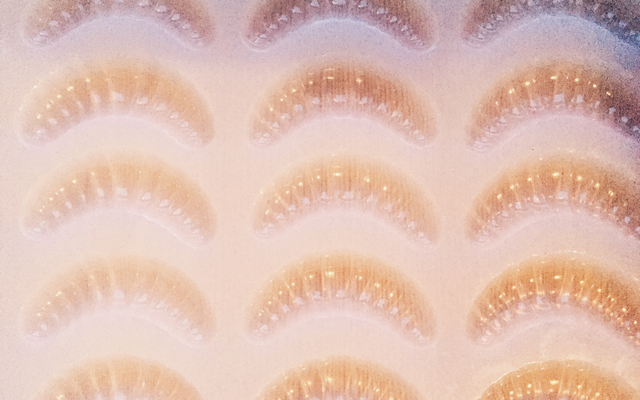

Task 1: "Volkonsky"

The Volkonsky confectionery production site set a task to make silicone forms of "Stones" of a smaller size than they had. Our team has performed 3D modeling, manufacturing and post-processing of master models, as well as casting in silicone. Despite the tight deadlines, the shipment of finished products was on schedule.

Task 2: "International Flavors & Fragrances"

International Flavors & Fragrances set the task to make silicone molds with the company logo, as well as swivel stands for rubik's cube with painting and PET plastic inserts. After agreeing on the sizes, master models were modeled and manufactured, their post-processing and casting in silicone were carried out. A swivel mechanism was developed for the stands, taking into account the requirements for stability and rotation. The elements of the stand were cut out of plywood, painted and assembled, after which the elements were made of PET plastic. The work was done a little ahead of schedule.

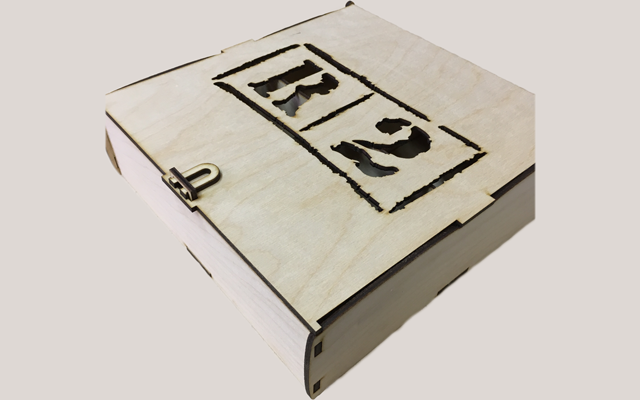

In addition to the production of confectionery equipment, our company can produce packaging from plywood: boxes of various configurations.

Task 3: "R2"

"R2" company set the task to make gift boxes of the specified size with their logo. After agreeing on all the necessary features, we started to work, made test samples that showed the design weaknesses. They finalized the design of the boxes, in coordination, optimized the logo for the requirements of the equipment, after which they made the whole batch. The work was completed on time.

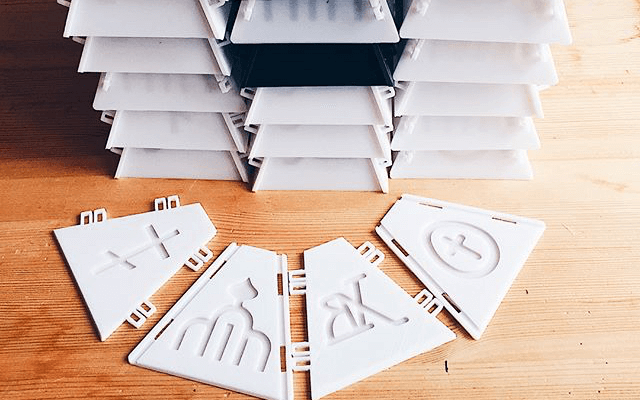

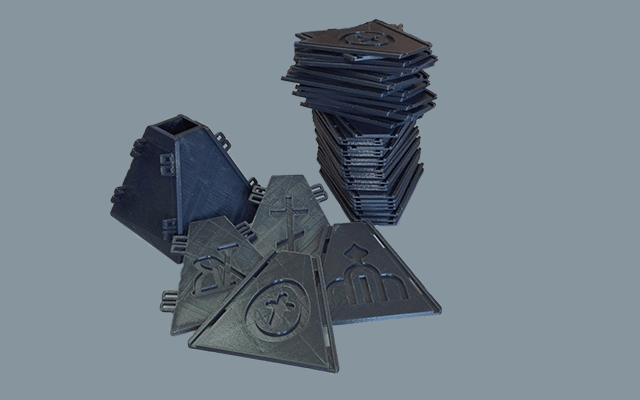

Task 4: "VladHleb"

"Vladhleb" company set the task to make a prefabricated plastic mold according to their analogue with changes. The form consists of 4 plastic panels with a pattern. 2 drawings were in original form, 2 drawings needed to be added.

As part of the task, a new mold was modeled, and the required number of sets was made.